Manufacturers, what if tomorrow’s water were already in your plant ?

AQUALYSE’s electrochemical process offers an economical and eco-friendly way to treat and reuse your industrial wastewater.

Our expertise

We analyze our clients’ specific challenges and address them with our innovative electrochemical process.

The Aqualyse process reduces capital expenditures and offsets operating costs through:

- lower discharge fees and taxes,

- significant reduction in chemical usage and sludge volume,

- and, where feasible, reuse of treated wastewater.

3. Customized solutions

All our equipment is custom-designed following a three-phase feasibility and sizing study.

This study is conducted both in our lab and directly on the client’s industrial site during phase 3.

4. Design, production, installation, maintenance

We oversee the entire value chain – from design to production, installation to maintenance – and the operational monitoring of our solutions.

Proven performance

- Highly Effective on Micropollutants and PFAS

- The following dissolved compounds can be treated by oxidation:

- Nitrites

- Sulfites

- Cyanides

- Chromates

- Fluorides

- Phosphors

- Nitrogen

- Highly-effective results for:

- Heavy metals

- Hydrocarbons

- Pesticides

- Radioactive isotopes

- Treats hard and soluble COD, colloids and the least degradable materials.

- Bactericidal and virucidal action due to an electrical field which leads to water disinfection and decontamination.

Advantages

- Sludge volume less than 3% of the initial volume to be treated (10 to 30 times less than a traditional process).

Denser and less hydrophilic sludge, easier flotation and sedimentation. - Sludge is optimized and wastewater biodegradability improved given the non-toxicity of the metal forms used.

- None, or few, chemical reagents (flocculants, coagulants and polymers, etc.).

- Less sensitive to varying chemical compositions, filler concentrations and pollutants, than physico-chemical installations.

- astly-reduced odors, both biological and chemical.

- Compact system which requires little space, easy to move, no or little civil engineering.

- Rapid return on investment, very low operating costs.

- May be used as an additional treatment for specific pollutants.

- Simplifies downstream biological treatments.

- Enables seasonal extra loads to be handled or total treatment capacity to be increased.

Applications

- Tanneries and taweries

- Textile industry

- Industrial laundries

- Mines and quarries

- Metal surface treatment

- Electronics industry

- Mechanical industry

- Abattoirs

- Meat, salting, salad dressing and emulsified sauces industries

- Canned seafood industries

- Canned fruit and vegetable industries

- Dairy and cheese industries

- Pharmaceutical industry

Hospitals and clinics - LV and CV cleaning stations

- And so much more…

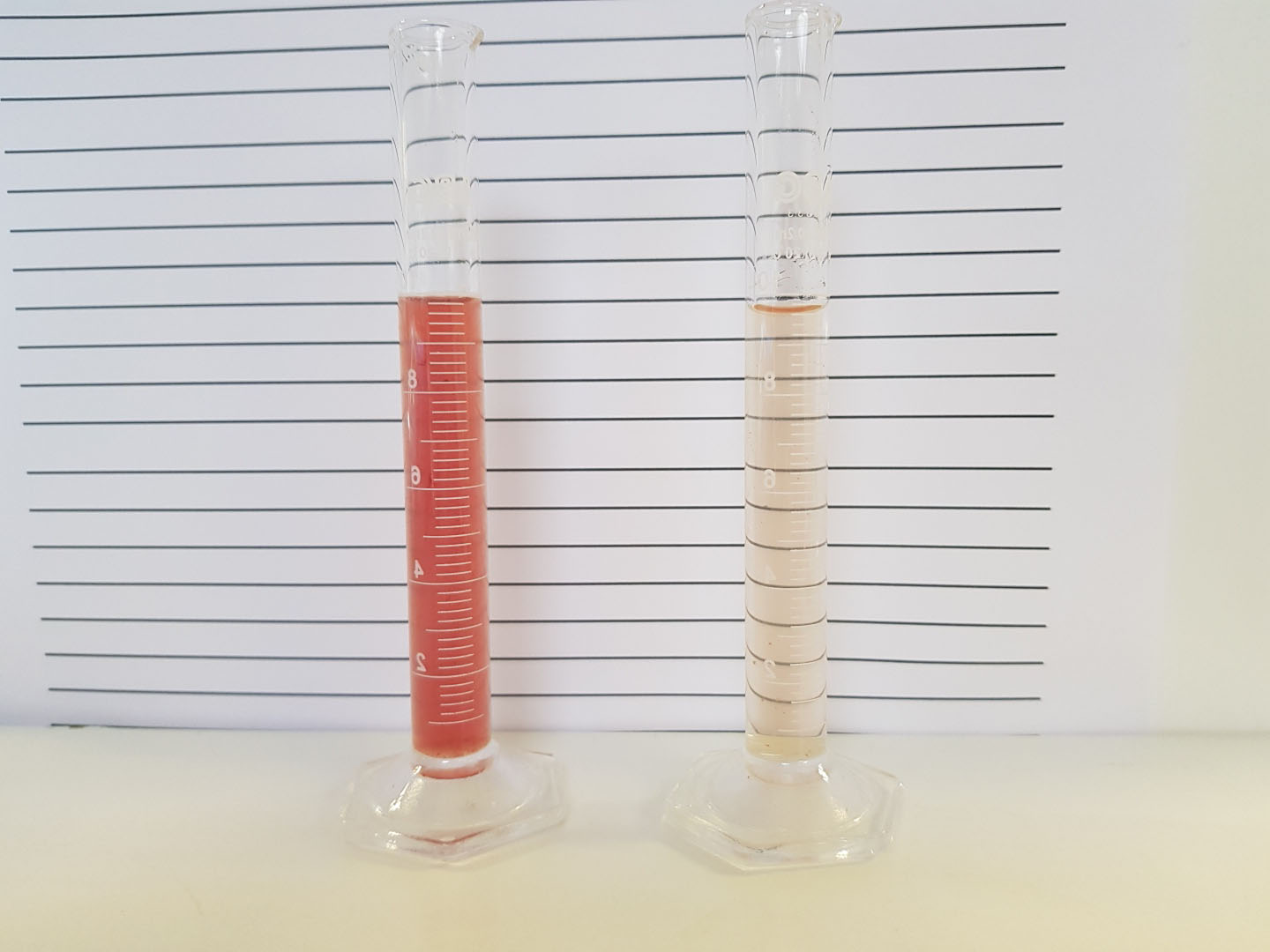

Electrocoagulated Tannery Effluents

Tannery effluent treatment and results.

AQUALYSE technology

is based on the following science and techniques:

- Electrolysis

- Solution chemistry

- Electrocoagulation

- Electroflocculation

The controlled dissolution of specific soluble electrodes creates coagulating and flocculating electrical charges which, without added chemicals, enable the following:

the destabilization of suspended and dissolved pollutants such as:

- metals,

- organic matter,

- suspended matter,

- colloids,

by precipitating them and separating them from wastewater.

Slaughterhouse Effluent – Before/After Electrocoagulation Treatment

Vegetable-Tanned Tannery Effluent at Various pH – Before/After Electrocoagulation

Industrial Laundry Effluent – Before/After Electrocoagulation Treatment

Our processes

1. PRELIMINARY STUDIES

From the first contact, we analyze your site data (effluent characteristics, regulatory constraints, potential reuse objectives). This step allows us to assess the theoretical feasibility of the proposed treatment.

This analysis is free of charge and non-binding.

2. Feasibility Study and Sizing

Our expertise is structured into four successive phases :

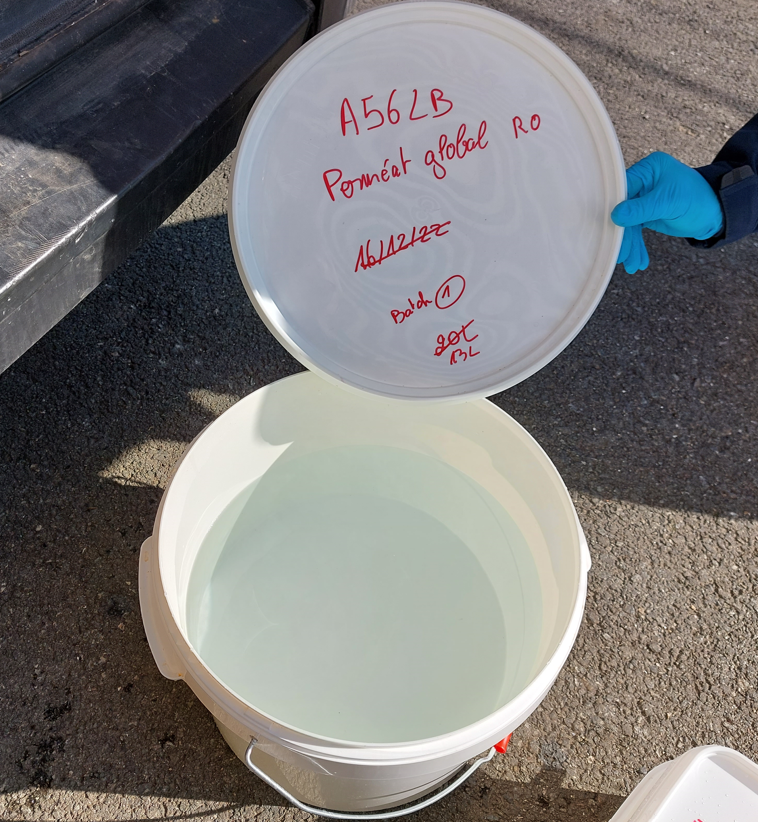

Phase 1 – Laboratory Testing

We collect samples from your site to conduct a series of small-scale tests in our laboratory.

Objective: Identify the most effective treatment configuration.

An interim report (No. 1) is provided at the end of this phase.

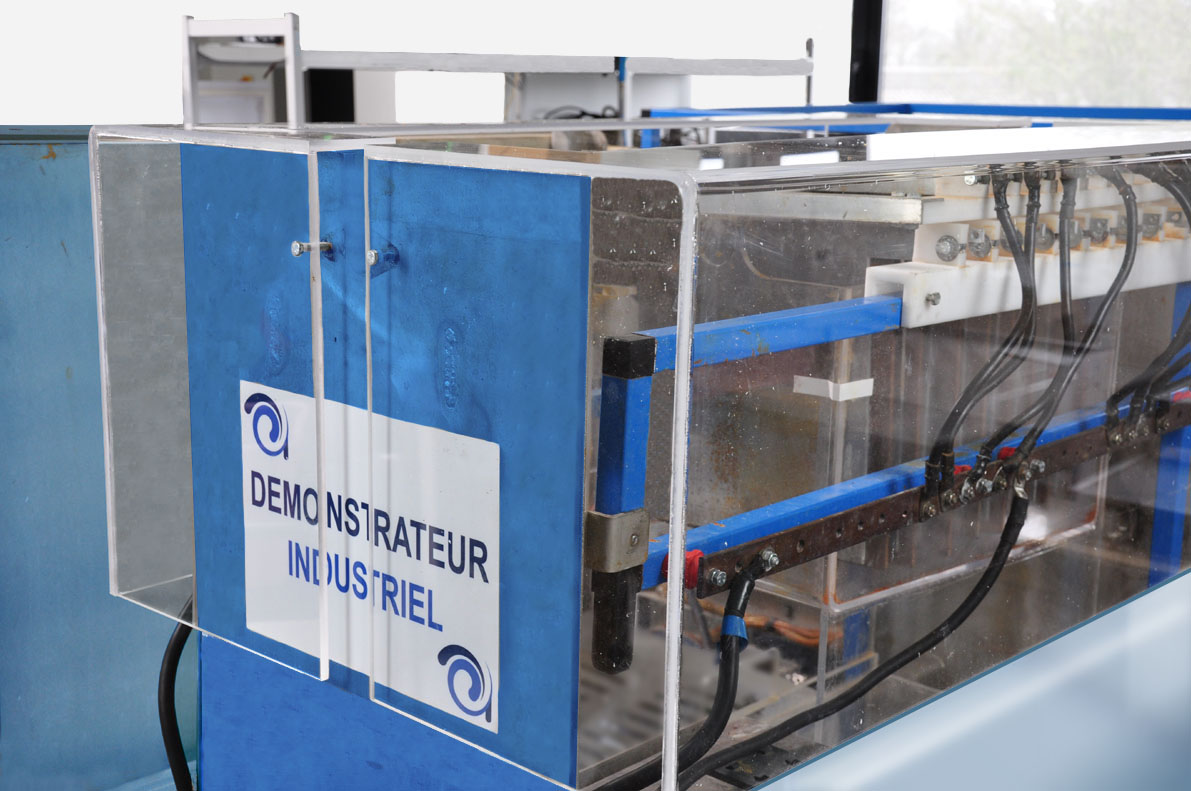

Phase 2 – Pre-Industrial Testing at Our Ploufragan Site

We test the treatment configuration selected in Phase 1 on our static industrial pilot unit to optimize energy consumption and electrode lifespan.

Objective: Maximize the efficiency of the selected configuration.

An interim report (No. 2) is provided at the end of this phase.

Phase 3 – Pre-Industrial Testing Under Real Conditions at Your Site

Using our mobile industrial pilot unit, we validate the treatment performance under real-world conditions on your site.

Objective: Industrial validation of the targets defined prior to Phase 1, on-site.

An interim report (No. 3) is provided at the end of this phase.

Phase 4 – Synthesis and Final Sizing

We define the technical parameters of the future installation.

A complete summary is provided, including the drafting of the technical specifications, a budgetary proposal, and the manufacturing contract.

3. Industrial Equipment Design and Production of Your Equipment

Once the manufacturing contract is signed, we initiate the production of your system:

- Design by our engineering department

- Technical drawings

- Procurement and in-workshop set up

- Internal technical acceptance

- On-site delivery, commissioning, and performance validation

- Final acceptance 60 days after commissioning

With Aqualyse, you benefit from expert support at every stage, a turnkey solution, and a dedicated team committed to delivering sustainable and measurable performance.

Mobile Industrial Pilot Unit

Electrochemical Cell Rack

Fish Cannery Effluents After Dual Electrochemical and Membrane Treatment – Reuse-Ready

Our partners

Posts

test 2

c'est le meme article

AQUALYSE ensures that your data, which is collected on our aqualyse.net website, is processed in compliance with the General Data Protection Regulation (GDPR) and the Data Protection Act. Please refer to our Privacy Policy and Legal notices for more information about your rights, particularly your right to withdraw your consent to the use of the data collected via this form.