Today’s manufacturers,

are aware that production lines which do not include effective wastewater treatment may be shut down.

With Aqualyse technology, you can manage your complex wastewater at minimum cost.

The AQUALYSE electrolysis process makes economic and environmental sense and fully complies to new, ever-stricter, industrial wastewater treatment standards.

Our expertise

1. Complex industrial wastewater treatment

We analyze each specific customer need before applying our innovative process to provide a solution.

2. Cost-effective solutions

The Aqualyse process reduces investment costs and neutralizes operational costs by making savings on discharge fees and taxes, radically reducing the use of chemicals and, therefore, sludge volumes, and by sometimes re-using treated water.

3. Customized solutions

We systematically carry out a feasibility study in our lab and at the customer’s industrial site before applying our tailor-made solutions.

4. Design, production, installation, maintenance

We oversee the entire wastewater treatment chain – from design to production, installation to maintenance – and the operational monitoring of our solutions.

Proven performance

– Highly-effective results for micro-pollutants.

– The following dissolved compounds can be treated by oxidation:

– Nitrites

– Sulfites

– Cyanides

– Chromates

– Fluorides

– Phosphors

– Nitrogen

– Highly-effective results for:

– Heavy metals

– Hydrocarbons

– Pesticides

– Radioactive isotopes

– Treats hard and soluble COD, colloids and the least degradable materials.

– Bactericidal and virucidal action due to an electrical field which leads to water disinfection and decontamination.

Advantages

– Sludge volume less than 3% of the initial volume to be treated (10 times less than a traditional process).

Denser and less hydrophilic sludge, easier flotation and sedimentation.

– Sludge is optimized and wastewater biodegradability improved given the non-toxicity of the metal forms used.

– None, or few, chemical reagents (flocculants, coagulants and polymers, etc.).

– Less sensitive to varying chemical compositions, filler concentrations and pollutants, than physico-chemical installations.

– Vastly-reduced odors, both biological and chemical.

– Compact system which requires little space, easy to move, no or little civil engineering.

– Rapid return on investment, very low operating costs.

– May be used as an additional treatment for specific pollutants.

– Simplifies downstream biological treatments.

– Enables seasonal extra loads to be handled or total treatment capacity to be increased.

Applications

– Tanneries and taweries

– Textile industry

– Industrial laundries

– Mines and quarries

– Metal surface treatment

– Electronics industry

– Mechanical industry

– Abattoirs

-Meat, salting, salad dressing and emulsified sauces industries

– Canned seafood industries

– Canned fruit and vegetable industries

– Dairy and cheese industries

– Pharmaceutical industry

– Hospitals and clinics

– LV and CV cleaning stations

And so much more…

*Click on an item to download a form

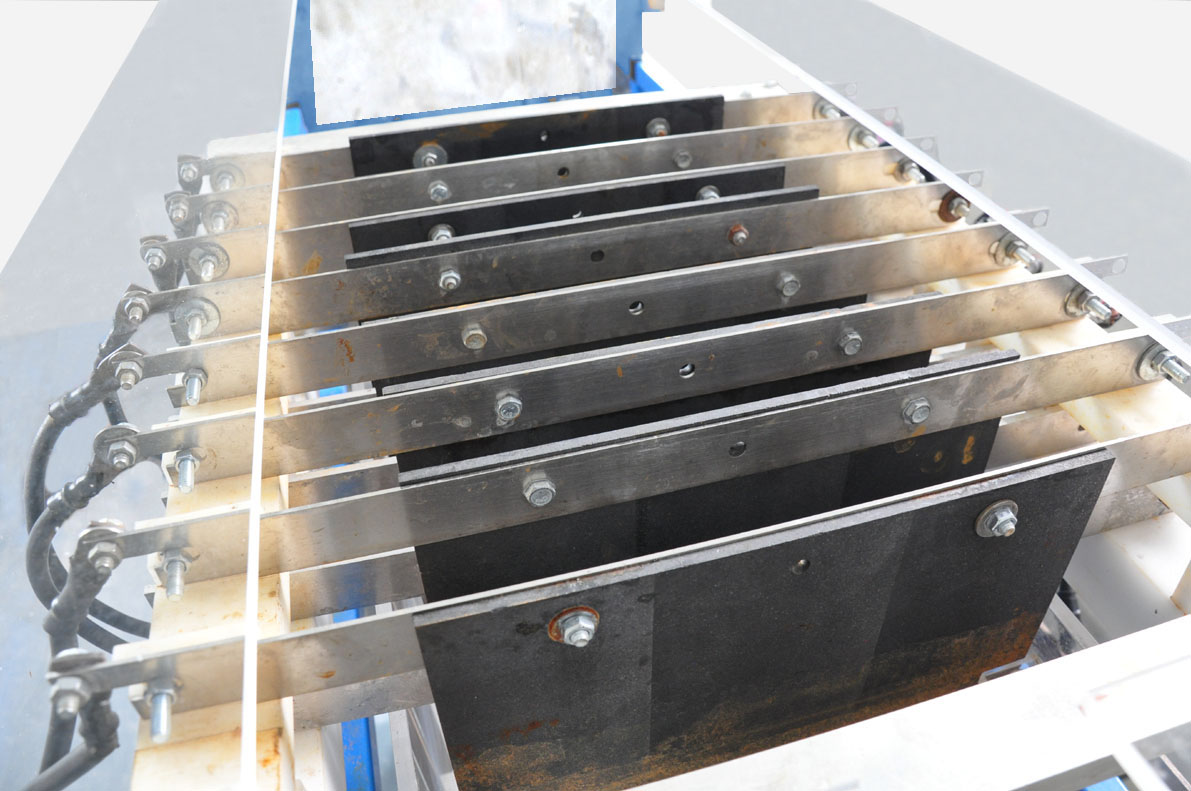

AQUALYSE technology

is based on the following science and techniques:

– Electrolysis

– Solution chemistry

– Electrocoagulation

– Electroflocculation

The controlled dissolution of specific soluble electrodes creates coagulating and flocculating electrical charges which, without added chemicals, enable the following:

the destabilization of suspended and dissolved pollutants such as: metals,

organic matter,

suspended matter,

colloids,

by precipitating them and separating them from wastewater.

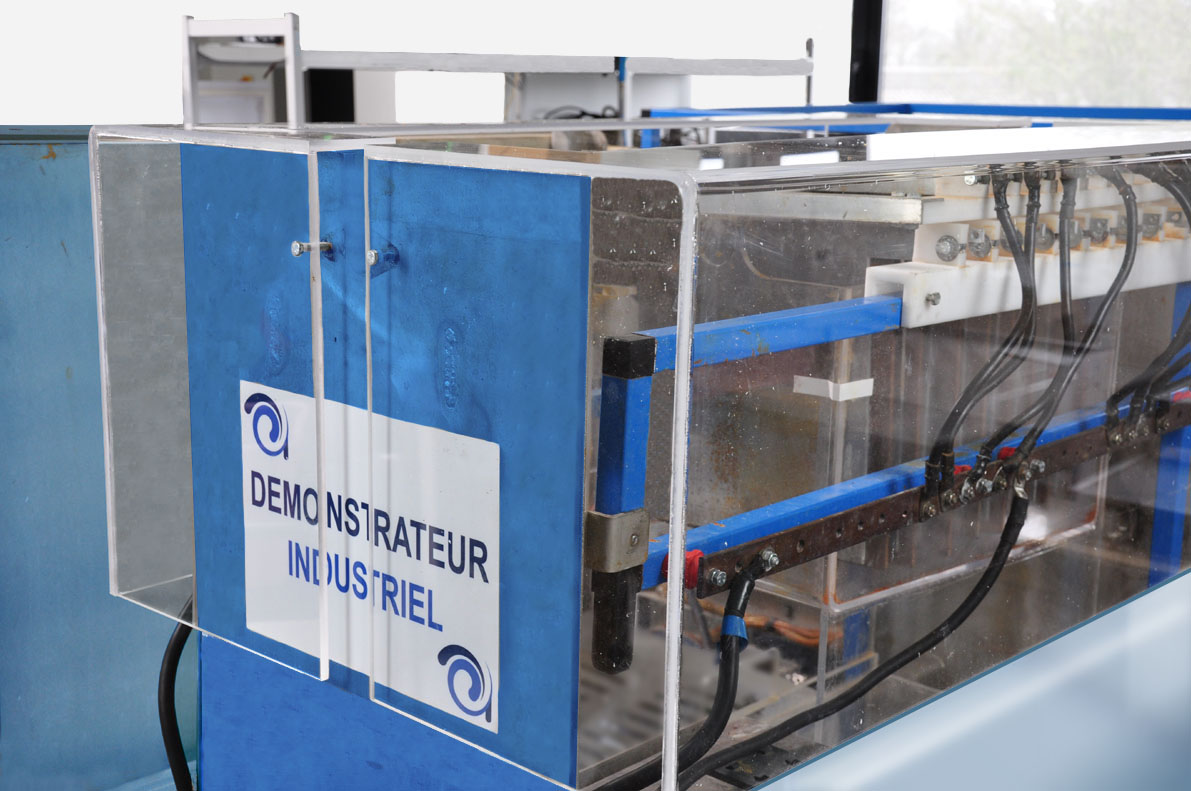

Our processes

1. PRELIMINARY STUDIES

The information provided by the customer is assessed during the initial study and feasibility phase, to check the theoretical feasibility of our treatment.

2. FEASIBILTY STUDIES

Phase 1 Lab – Reduced volume tests. Wastewater samples taken from the customer’s site and tested in our lab. Parameter optimization.

Phase 2 On-site –

Pre-industrial volume tests at the customer’s site with our mobile industrial demonstrator.

This phase enables lab test optimization and validation in situ.

3. INDUSTRIAL EQUIPMENT DESIGN AND PRODUCTION

– Draft contractual specifications and sales contract

– Engineering and Design

– Technical drawings

– Work order

– Supplies

– Machine assembly

– Workshop set up and Quality Control

-On-site delivery and installation

– On-site performance report

– Withdrawal of reservation

AQUALYSE ensures that your data, which is collected on our aqualyse.net website, is processed in compliance with the General Data Protection Regulation (GDPR) and the Data Protection Act. Please refer to our Privacy Policy and Legal notices for more information about your rights, particularly your right to withdraw your consent to the use of the data collected via this form.